ACTUALITY

Blog

21 April 2021

CHUMILLAS TECHNOLOGY installs COLORJET 20 at PERONDA GROUP

CHUMILLAS TECHNOLOGY implements the COLORJET 20, the disruptive dry coloring system, with the aim of expanding the large-format ceramic line of PERONDA GROUP.

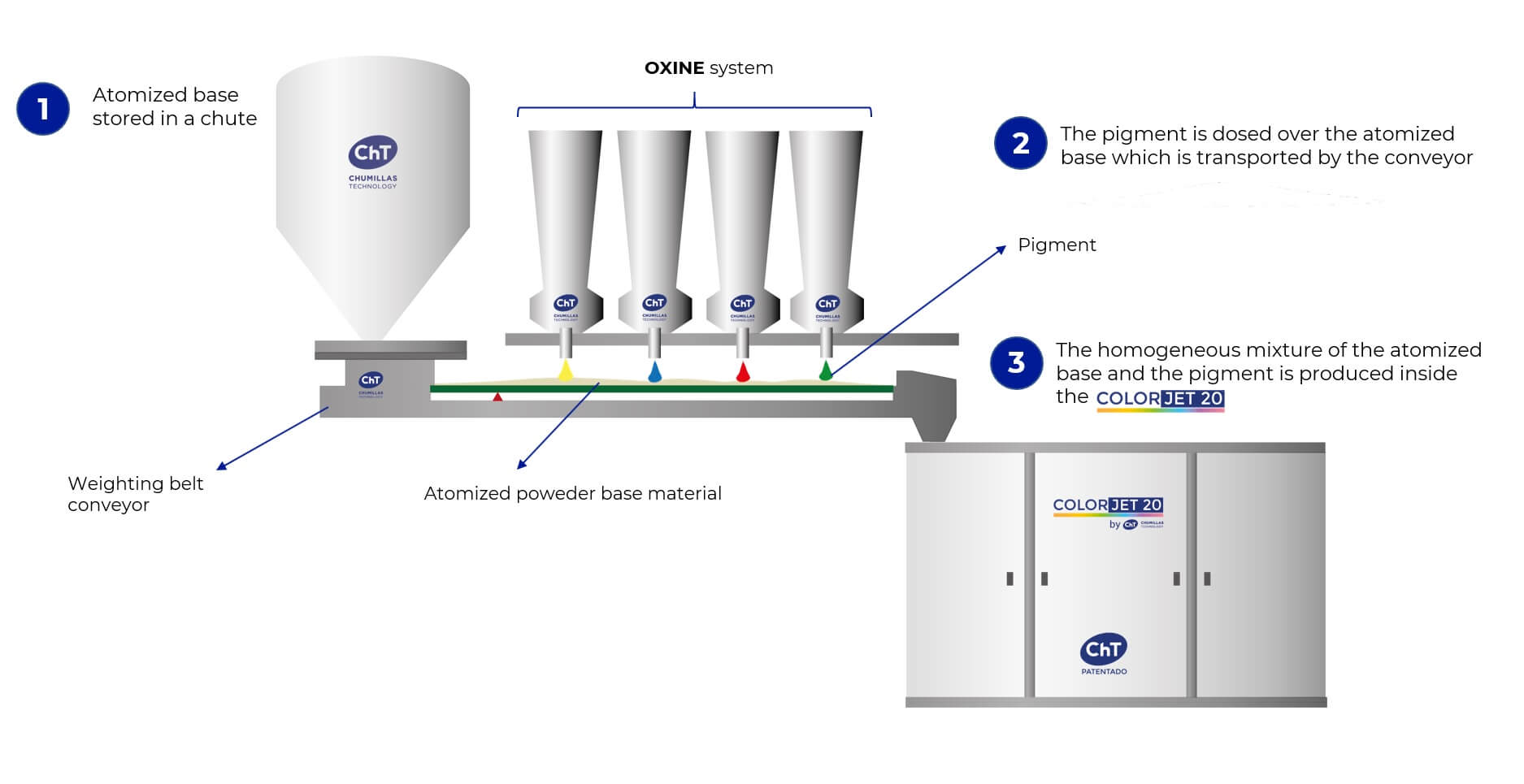

COLORJET 20 is the latest dry coloring technology on the market. It is designed by the R&D and engineering department of CHUMILLAS TECHNOLOGY and allows to achieve a production of 20t/h. In this patented solution, there are no mechanical components in the mixture, and it reduces cleaning times and product change.

A relationship with history

The relationship with PERONDA GROUP dates to 2002 where, as explained its Chief Innovation Officer (CINO), Javier Sanjuan “installed the first dry coloration system by CHUMILLAS TECHNOLOGY”. Since then, it has been followed by another 2 coloring systems for the new production plant and a complete installation for the new large-format ceramic line.

It was in 2020 when “we need to expand the large-format ceramic line with a new dry coloring system. We transferred this requirement to CHUMILLAS TECHNOLOGY and went into the COLORJET 20 installation project,” explains Sanjuan.

At that time, as explained by the Chief Executive Officer (CEO) of CHUMILLAS TECHNOLOGY, David Chumillas, the new COLORJET 20 coloring system “was being tested in the TechLAB pilot plant”. For its part, Sanjuan indicates that “at PERONDA GROUP we are always committed to the latest technology in the market. For these reason we established the collaboration in this project because it was a good opportunity to install a new generation coloring system in our company”.

A successful COLORJET 20 implementation process

Jorge Denia, Production Technician of Plant 2 of PERONDA GROUP, confirms the satisfaction of the team during the installation of COLORJET 20. “This process started with the tests we carried out at the TechLAB pilot plant. From the first coloration, we got pieces that could have been the finals,” says Denia.

The previous work we have done together with PERONDA GROUP has been crucial for a successful start-up. Carlos Chumillas, Chief Technical Officer (CTO) of CHUMILLAS TECHNOLOGY, assures that “the implementation of the COLORJET 20 has been smooth thanks to the good communication with PERONDA GROUP and the previous tests carried out at TechLAB”. “Having a research laboratory in which we have been able to test the product and where the PERONDA GROUP has been able to see the final tests, has allowed us to adjust the start-up prior to implementation of the solution,” adds the company’s CTO.

Main objectives of the COLORJET 20 installation

Sanjuan explains that “the main objective of this project was to provide the large format line with a new coloring machine with greater production capacity to feed that line. The COLORJET 20 perfectly covers this need”.

In the following image, we can observe the process of operation of the dry coloring system of CHUMILLAS TECHNOLOGY.

Another of the benefits highlighted the CINO of PERONDA GROUP, “is the ease of cleaning the solution in the face of product changes and the speed of changing the percentages of oxides. The flexibility of the COLORJET 20 makes the production work easier”. In addition, Sanjuan confirms, “this latest coloring system gives us the possibility to expand our range of colors”.

David Chumillas, for his part, is grateful for “the trust that PERONDA GROUP has placed in the CHUMILLAS TECHNOLOGY, since it has led to the implementation of a revolutionary dry coloration system made in Spain“.