ACTUALITY

Blog

6 October 2023

CHUMILLAS TECHNOLOGY designs a glass micronization plant for ONIX MOSAICO

ONIX Mosaico, the leading company in the manufacture of vitreous mosaic, relies on CHUMILLAS TECHNOLOGY for the design and implementation of a glass micronization plant.

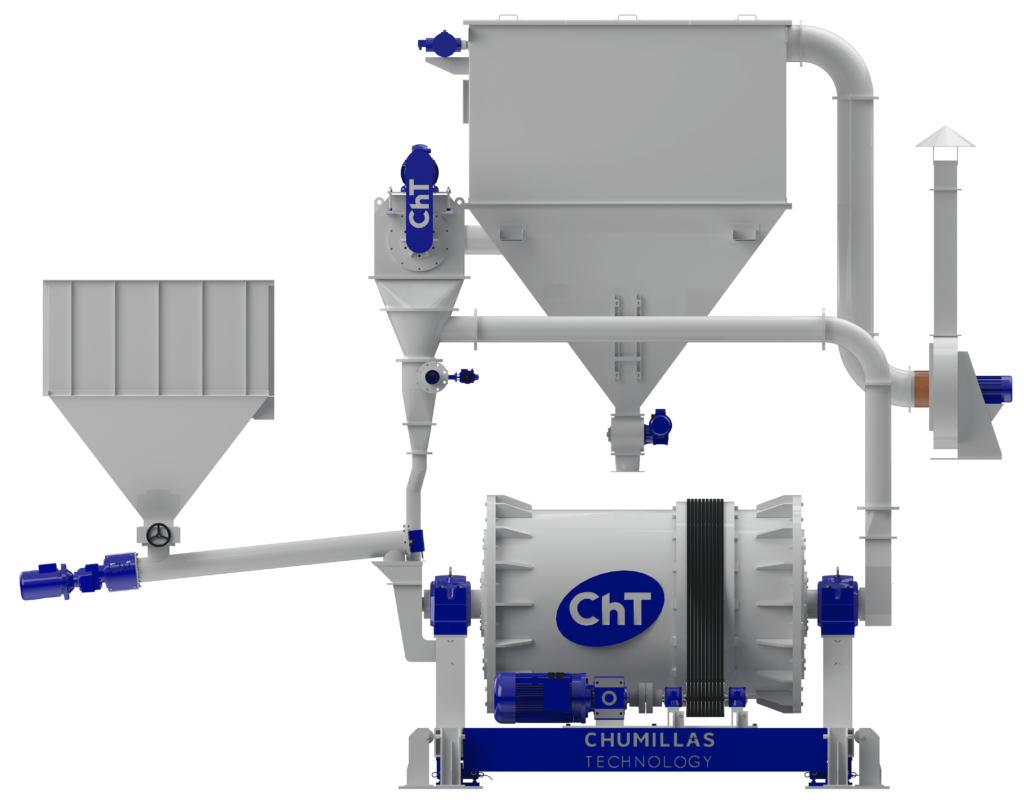

This plant includes the MIKROS micronization system designed by the engineering department of CHUMILLAS TECHNOLOGY, including different elements that allow the implementation of a glass micronization and classification system.

MIKROS micronization system infographic

Benefits of MIKROS micronization system

This system is designed for the dry micronization of various raw materials, and to ensure low energy consumption in high production for particles smaller than 10 microns. In addition, it is fully automated and ensures the quality of the micronized product. Another of the main benefits of this micronization system is the ability to carry out continuous measurements of both the supplied and the resulting product.

This solution also allows this separation to be carried out so that the optimal micronized glass is stored and so that the glass that has not yet reached the appropriate size returns to the mill to continue with the micronization.

With this installation CHUMILLAS TECHNOLOGY reinforces its position in the micronization process in various industrial sectors.