EQUIPMENT AND SOLUTIONSGranulation

Granulation process consists of joining a set of small primary particles of raw materials or finely divided or pulverized substances to form a uniform granulate of greater size and density by pressure or by the addition of a agglutinative dispersed in a liquid. It is the operation contrary to the division.

In general, this granulation process obtains a granulate of ranges from 0.1 to 2 millimeters in size.

This process has lots of advantages: it increases the size of the particles, improving the fluidity, improving the solubility, avoiding the volatility of the powders, improving the physical appearance and avoiding the segregation of the raw materials.

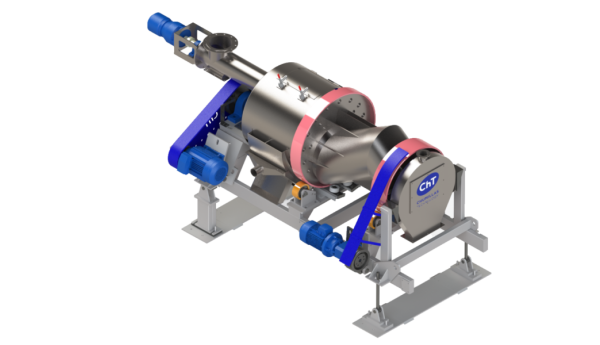

In Chumillas Technology we are experts in granulation machinery and we have four different devices that will help you during the granulation process and are designed for different industrial sectors such as ceramics, chemistry, mining and / or agri-food.

Looking for more information?

Write us your questions and requirements. We will contact you.