ACTUALITY

Blog

26 January 2021

Chumillas Technology brings its innovative technology to Argenta’s new production plant

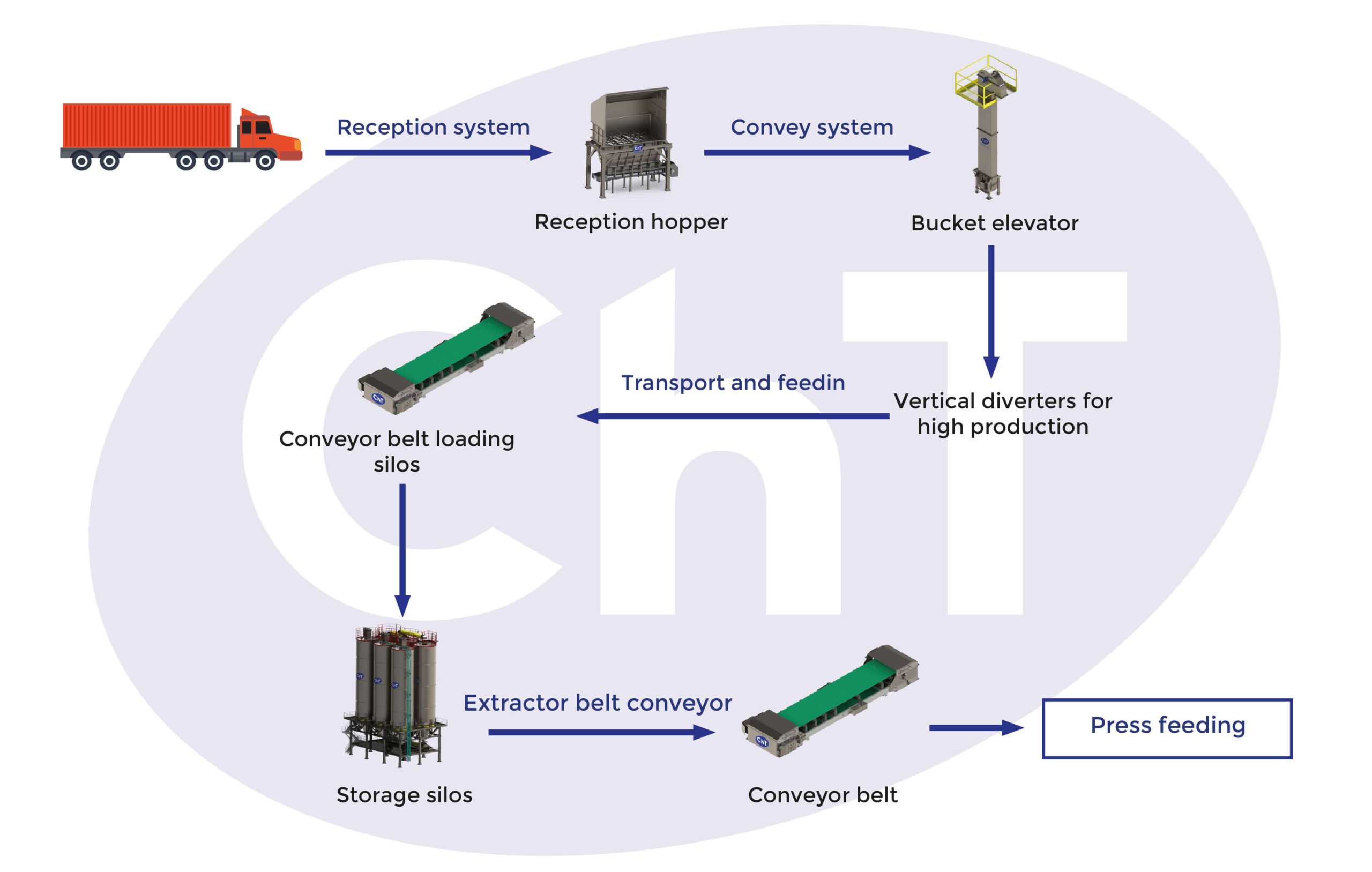

Chumillas Technology has engineered and manufactured a new press reception and feeding plant in Argenta. This installation includes the most innovative technology to increase the production capacity of porcelain stoneware.

The teamwork of Chumillas Technology relies on cooperation, guidance, design, manufacture, assembly and commissioning of the facility. This project includes storage silos with 1,500 tons of capacity, reception systems and different mechanical transport solutions.

This solid handling technology increases the performance of the ceramic production lines making them more efficient and productive.

On the image below, we can see a ceramic tile facility with the aforementioned solutions:

Turnkey solution for a production plant

The engineering team of Chumillas Technology had carried outa preliminary study of Argenta’s needs. As a result, we have presented the project’s scope, manufacturing, assembly and commissioning schedule proposal. Chumillas Technology has been helping ceramic factories to optimize their production processes since 1981.

In this video we can see the manufacture and transport of silos for Argenta:

Process research laboratory for ceramic companies

The processes included in a production plant are available at the TechLAB pilot plant. We are making reference on our research laboratory equipped with industrial machinery required to perform tests of the project and to design new solutions. This exclusive innovation space at Chumillas Technology allows to provide factories with a research space, save costs, ensure the final result and to prevent problems related to production lines.