ACTUALITY

Blog

17 October 2022

Reduce energy consumption with the COLORJET 20 system

CHUMILLAS TECHNOLOGY designed the COLORJET 20 system for the commissioning of the dry colouring process in the production lines of tiles of various formats. This patented and latest technology, in the field of mixing systems, is presented as a sustainable solution because it allows saving more than 50% the energy consumption of the dry colouring process.

Energy consumption under the spotlight

In the current context it is important that factories are aware of production costs and monitor and analyse their energy consumption. While, we, as manufacturers of machinery for the implementation of production processes, have the duty to design and offer sustainable solutions that facilitate cost savings to factories, maintaining the quality and safety of the final product.

As an example of this purpose in which we work, we put as an example the solution for the ceramic sector that we showed a few weeks ago at the TECNA fair that was held in Rimini, Italy: the dry colouring system COLORJET 20.

According to the studies carried out by our engineering and R&D team, which have taken variables such as the particle size of the atomized, the percentage of oxides applied, particle size, humidity or mixing speed, among others, it is concluded that our dry colouring system COLORJET 20 allows to reduce by more than 50% the energy consumption compared to other colouring solutions on the market.

Without going into technical details, this solution facilitates the reduction of energy costs for the following reasons:

- Produce more, in less time: Compared to traditional dry dyeing solutions, our COLORJET 20 system achieves yields of up to 20 tons hour. Therefore, more color is produced in less time.

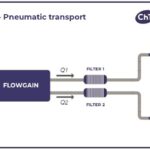

- Removal of mechanical elements in the mixture: During the mixing phase of the atomization with the pigment, no mechanical elements are used to execute the mixture that limit the production capacity.

With this system we make it easier for ceramics to achieve their objectives of cost savings, increased production and simplification of their facilities, while maintaining and even improving the quality of their final product.